About Us

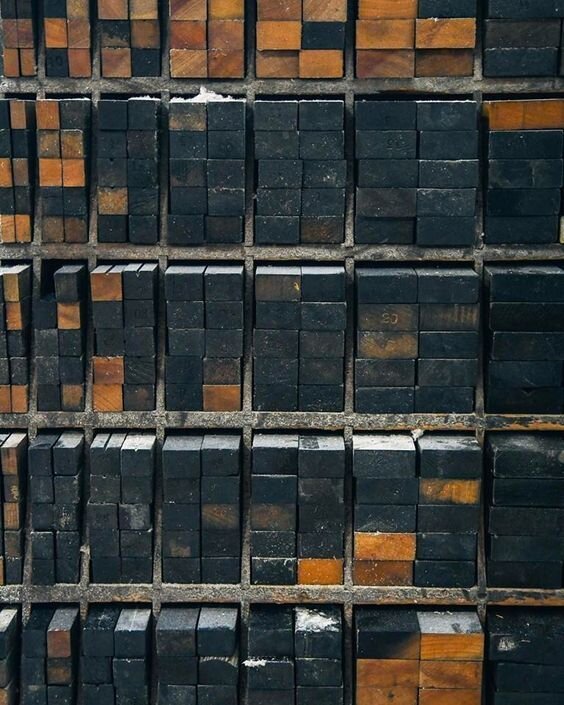

In 2014 I realized that printmaking was the missing component digital design lacked. That's when I started M.C. Pressure. Back then, we were a small press on a table in my roommate’s kitchen. Since then the company has grown: acquiring new presses, expanding the line, and collaborating on several custom pieces.

Ryan Tempro, Founder and Printmaker

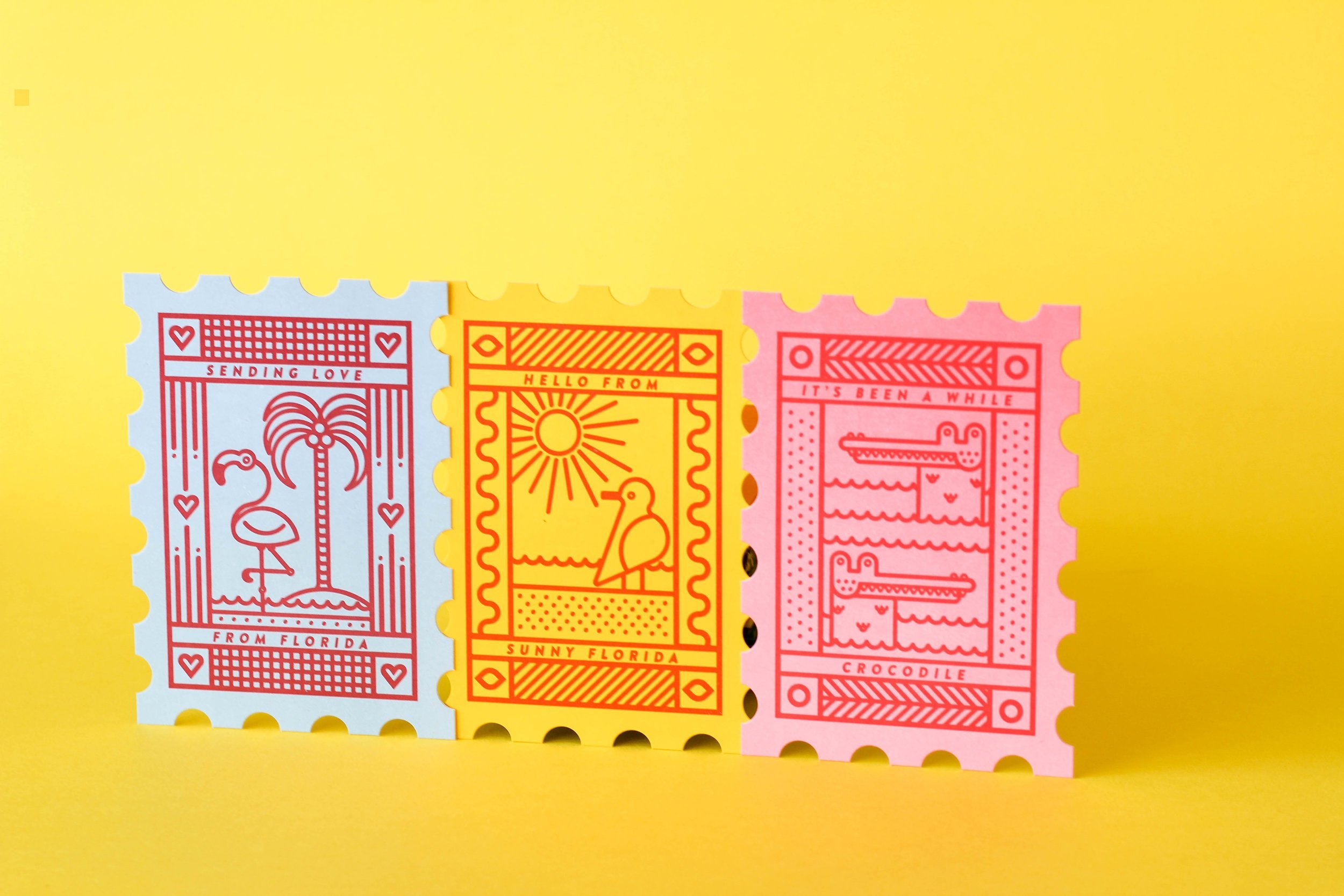

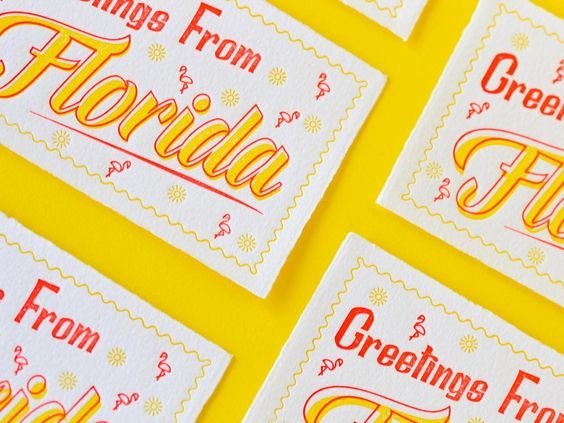

M.C.Pressure is a letterpress print shop based out of the Nation's Oldest City, Saint Augustine, Florida. Our two-person team, and one good boy, is dedicated to bringing traditional printmaking to graphic design.

Our company name is based off, suprise surprise, a pun. M.C.Escher was always an inspiration to Ryan Tempro. So, combining the love of his work and pressure techniques involved with letterpress- M.C.Pressure was born!

What We Do:

The process of letterpress starts with an idea. We'll sketch an idea and then transfer it to a digital format. That digital file then becomes a printing plate. We’ll put the plate onto the press and let the machine work its magic. The machines rollers will ink the plate, moves the paper into the press, and debosses the design into the paper. This creates a texture that is exclusive to letterpress.

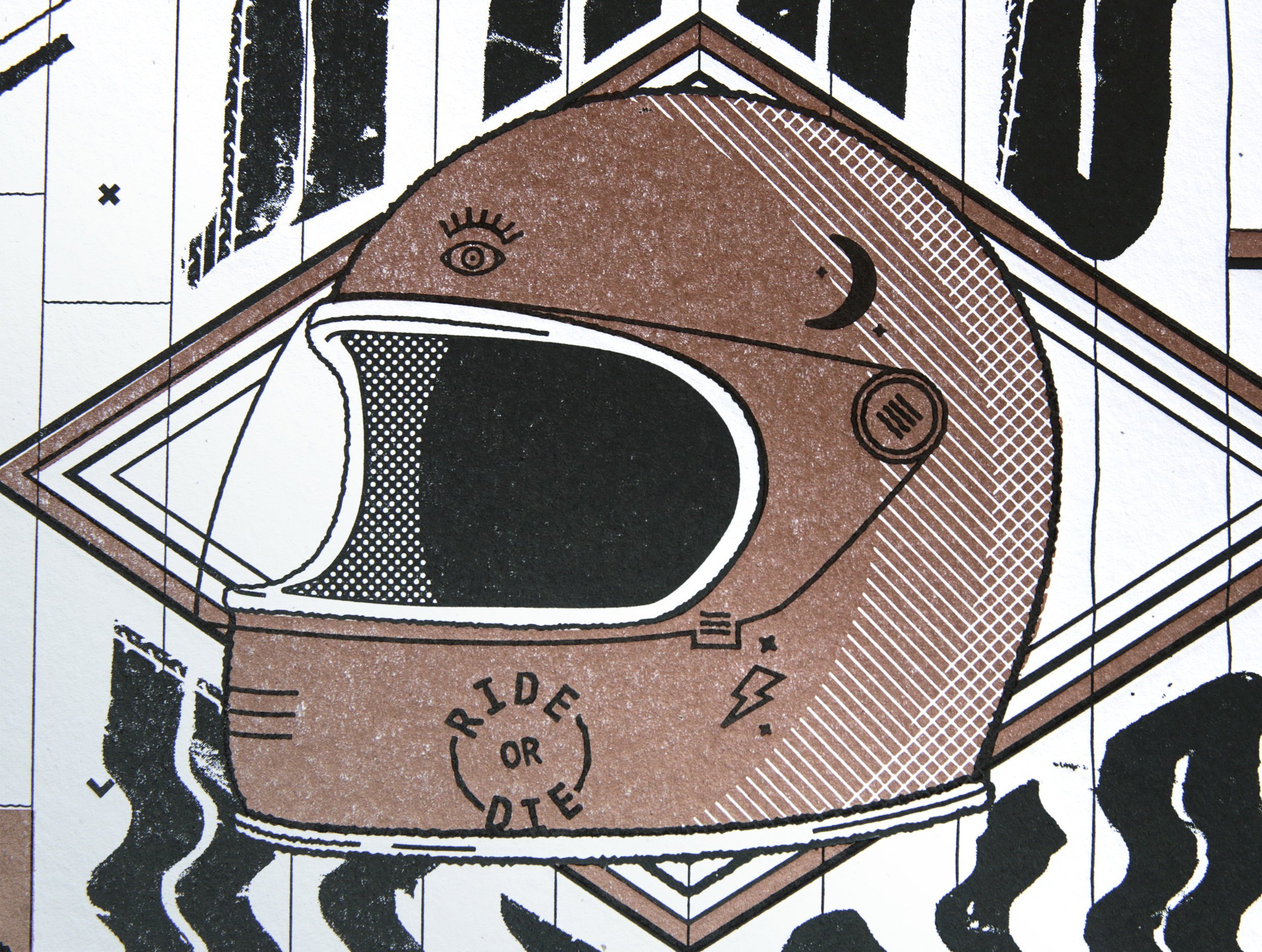

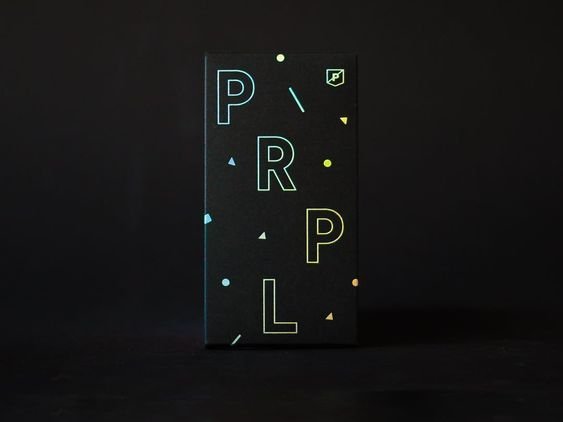

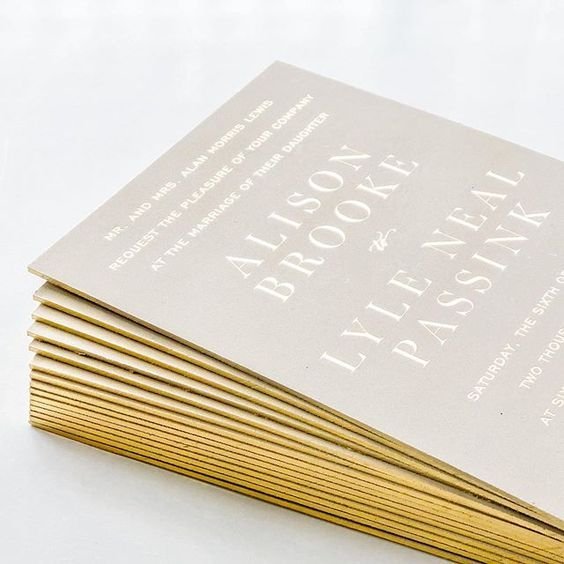

Another printmaking process we offer is Hot Foil Stamping we have a Heidelberg GTP from 1972, and it’s a beast. This technique parallels letterpress. The machine heats up a copper die and then presses the design into foil and lays it into the paper. Foil allows for color to pop. Foil stamping allows for light colors to appear on dark paper.

Printmaking feels special in that it allows for a handmade touch. The old technology of the presses combines with new graphic design techniques. This pairing creates something that feels one of a kind and is something that you will want to hold onto.

let’s work

together

Our Processes

Our studio specializes in the following three processes: letterpress, hot foil stamping, and embossing. Below we describe each processes’ brief history, style of print, and color capabilities. To learn more about each, please don’t hesitate to reach out! Read more on each of the processes on our blog or pinterest.

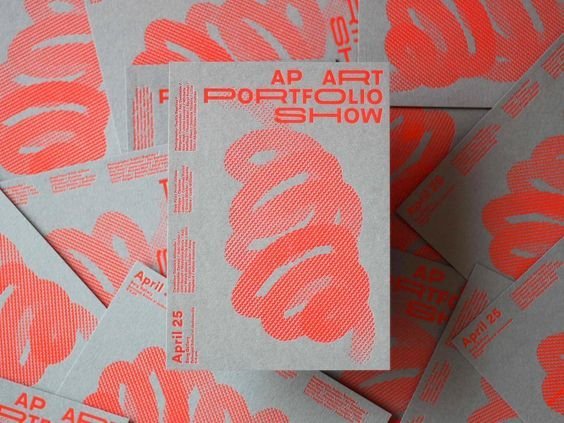

Letterpress

About

One of the oldest forms of relief printing, Letterpress is a technique where a design forms an inked impression onto paper. With this process, the inks are opaque and are handled one at a time.

The Process

Think of letterpress plates like a stamp- designs are mirrored and raised onto a plate. We place the plate onto our letterpress and start printing. First, inked rollers roll onto the plate, only inking the raised design. Then the plate is pressed into paper, leaving behind a debossed image.

Letterpress allows for only one color to print at a time. Each plate coincides with a different color. So, a one-color design equals one plate while a two-color design requires two plates.

There may be subtleties in inking or impressions, making letterpress unique!

Letterpress is one of the oldest methods of relief printing, so the machines are often old and heavy. But they're built to last! We found that by using the old technology and combining it with modern techniques- the process is quicker, safer, and more unique.

Capabilities + Colors

Our studio offers Pantone Matching and specialty metallic inks.

All inks are transparent to some degree, so true color paring depends on paper color.

For example, think of a standard elementary school marker. On a piece of white paper, a yellow marker would appear yellow. But, on a blue piece of paper, the yellow is much more muted. A general rule of thumb is to stick with darker inks onto light-colored paper. For lighter colors on darker material, we might look into foil stamping (below) to achieve this result. Foils are more opaque and able to cover the darkness of the paper.

Check out our Letterpress Pinterest Board on for samples on the process.

Hot foil STamping

About

Similar to Letterpress, Foil Stamping forms a debossed texture of the design into the paper. Unlike letterpress, the machine heats a copper plate to press foil into the paper. The foil is not opaque, so paper colors will not show through.

The Process

Foil stamping is similar in process to letterpress with a few differences that stand out to us!

We use copper plates in-house for all foil jobs. Copper is an excellent material that can retain heat well over the press run, and also hard enough to be able to hold small details that might get lost with softer materials like magnesium.

No ink is involved with Foil Stamping. Instead, we use thin ribbons of foil. As the hot stamping die comes in contact with the foil, it presses into the paper and transfers the foil from the ribbon onto the paper.

Copper foil stamping plates are often more expensive than traditional letterpress plates, and therefore usually demands a higher price for these processes over letterpress. While metallic inks exist for letterpress, we've found that most people prefer metallic foil over metallic letterpress inks.

Capabilities + Colors

Foil is opaque so the color will print as shown no matter the paper color. Foils come in a variety of shades, metallics, and even as a scratch-off and holographic. You can create a dramatic effect with a light foil on darker papers or step up your packaging game.

Check out our Pinterest Board on Foil for samples on the process.